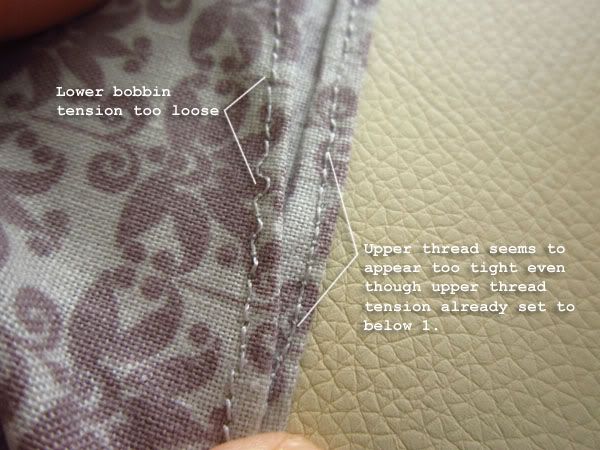

Yes, my machine did a tension mess again when I was sewing my It's the Pockets dress. I had already have my upper thread tension dropped to 1, but the upper thread still seemed tight. Dropping the upper thread tension by 1 tiny notch seemed to solve the upper thread problem, but the bottom thread was in a total mess (too loose).

After pondering over this problem, and after re-reading a post by Grosgrainfabulous about shirring using the Brother machine, I figured my bobbin case tension screw must have loosened somewhat due to my pretty heavy use of the machine over this past year. And that resulted in my need to drop my upper thread tension pretty drastically to match the tension of the bottom thread so that the stitches could appear reasonably even.

To solve this, I need to get to my bobbin case. Unlike Kathleen's (Grosgrainfabulous) Brother machine, my bobbin case is stuck to the machine (I guess I could remove the upper plate but the screws were too tight. edit: after reading the manual, you can use a coin to unscrew them). However, I managed to lift the bobbin case up a little and that was sufficient for me to tighten the screw:

If you are unsure of how to get to your bobbin case, here's a very short tutorial:

To adjust your bobbin thread to the correct tension, there's a bit of trial and error to be done. First, thread your machine with a thread of normal thickness. Next, set your upper thread tension to 4 (the normal setting). Then, tighten your bobbin case tension screw. Once done, set your machine to zig-zag stitch (if your machine does not have that, you can use a running stitch, but it might be harder to see) and start sewing.

If the stitches at the bottom look funky to you, it means the bottom bobbin tension is too tight. You'll need to loosen the screw a little. If it's the stitches on the top that look funky, tighten the screw a little. Repeat this step until both the top zig-zag stitches and bottom zig-zag stitches look even.

Here's how my stitches look like after re-adjusting:

Tuesday, February 07, 2012

Subscribe to:

Post Comments

(

Atom

)

44 comments :

When loading the bobine MAKE SURE that you catch not only the gray plastic guide but also the metal one under it.

I mean the thread has to cath both guides. I think the plastic one is supposed to make you pull the thread in such a way that you catch the metal guide. This at least for Brother xl-3750. This principle is similar to the threading mecanism that you pull down. Two guides are there for you but really what you are aiming is a small hook that enters the needle. Bonus when changing the presser foot, dont try to pry it of! There is a black botton at the back of the presser foot holder. Thank God I found out that timely!

Hi! Thanks for your input!

I guess you meant the tiny hook that's lying against my finger in the picture? Yep, it's exactly that portion that has come loose on this machine of mine (I've since passed it to my friend after mending the tension). After tightening the screw, it sews much better. =)

Talking about different Brother machines.. I find it interesting that they have "locked" the screw for the bobbin case in my newer Brother machine. (the screw is painted over with a layer of paint??)Which kinda sucks because Brother machine can't do shirring properly and one of the tricks is to tighten that screw! >< And for my cousin's machine, not too sure if she's pried off the bobbin case accidentally, but the whole thing was removable! O.O

And yes, the lady who sold me the machine did keep telling me to press that button at the back when changing presser foot. Hee! =) Perhaps I can have a post on that!

Thank you for this post. I have been having such trouble with my machine but just tightening that pesky screw has made all the difference. And my bobbin case was removable. It slipped right out and then right back in. Thank you again!

No probs, Juli! Glad that my post helped!

I have a brother and my case is removable but now I find that the case itself is loose so much that it causes the machine to make loud noises and makes the tension all out of sorts...not sure how I can fix this without having to take it in...help anyone?

Oh no! I'm so sorry to hear that. The case might have been misaligned.. Have you tried taking the case out and slotting it back?

I'm so happy to find this post! I'm a new sewer, and these little glitches are still uncharted territory for me. You are describing exactly what is happening with my Brother machine, right down to having to turn upper tension way down to 1. I think it might have happened, or at least the problem started, a little while back when I had a bad jam of fabric/fiber in the feed dogs and had to take things apart. I managed it okay, but I now suspect that wiggling parts out of and back into position must have loosened the screw. I took a look last night, and I do not believe the screw is 'locked' although it is painted. But it does not appear to be glued in place or anything. Couldn't be or it wouldn't have loosened, would it? I shall wait until I have time and a supply of patience for the trial and error portion, and will report back with results.

Thanks again!

Hi MacBee, no problem! Hope to hear good results from you!

Oh, also, do check if your bottom thread is also under the metal prong in the bobbin casing.

Thank you so much! I had cleaned and rewound bobbins and was about ready to just take my Brother XL3750 to the repair shop when I found your response in this thread. I found I had to press down the plastic guide flap and hold down the bobbin itself to get it to thread through BOTH the metal and plastic guide. If I do this, the tension top and bottom are great.

thanks SO much for posting this! i had a lot of trouble with the tension of my bobbin, but i didn't know how to fix it until i saw your pictures of the screw! can't tell you how relieved i was to see your post and it's the exact configuration of my own brother sewing machine. helped so much. thanks! (:

also, your blog looks really cool! looking forward to wandering around ^_^

This helped so much thank you!! I've been trying to fix this problem for a couple hours now. You're the best!

I was really freaking out for the last 3 weeks with this, been making gowns for my clients and apparently when I'm about to apply those bonings to the corset the bottom stitch is really screwed up, I tried to browse the website of brothers but the troubleshooting is no big help at all. then I stumbled on your page and I was so curious and tried it, i cleaned the inside part, tried to adjust the tensions etc and to my surprise my problem is solved! thanks to you, thanks for helping us with this, definitely saves a lot of money for repair and time as well! God Bless you

Thank You SO Much! This post kept me from launching my new sewing machine into space! I can now get back to sewing with a smile & be civil to the rest of the planet (I'm told I was a titch grumpy)! Thanks Again!

Thank You SO Much! This post kept me from launching my new sewing machine into space! I can now get back to sewing with a smile & be civil to the rest of the planet (I'm told I was a titch grumpy)! Thanks Again!

No problem, guys! Glad that this post is useful!

Hi! I am new to sewing and I was trying to sew buttons today but very time I get knots of thread at the bottom... nesting? I dont know what to do! I tried adjusting the bobbin screw one way and the other and nothing!!

Hey BoscAna, are you using a Brother machine? Is it a new machine? Also, are you using the right needle for the fabric and thread?

Firstly, do make sure that your bobbin thread is wound correctly on your bobbin and that the bobbin thread is also under the metal prong of the bobbin casing. This is very important!

Next, try dropping the tension of your upper thread and see if it sews better.

If that still doesn't work, then adjust the tension of the bobbin thread.

If adjusting tensions for both the upper thread and bottom thread are not helping, it might be that the bobbin casing is not sitting right in the bobbin casing holding area.

For some of our Brother machines, we can actually remove the bobbin casing. And sometimes, when the needle gets stuck in the bobbin casing, it will get shifted and mess up the tensions, causing the upper thread to get entangled. To solve the problem, I had to remove the needle plate cover, take out the bobbin casing and place it back at the right position (some trial and error here).

You saved my Silnylon tarp attempt. I was fine with the thicker Ripstop nylon but the 1.1oz Silnylon would not sew. I made the necessary adjustment to the bobbin tension and Magic!!!

I have the same machine you do and I took the bobbin holder out with out taking out any of the screws I was wondering how do I put it back in on the same machine . I'm a beginner so yeah I need help.

Hi Bill, glad that it helped!

To the reader just above this post:

Hi! Is it okay if you shoot me an email with a photo? I have since upgraded to another Brother machine, and I'm not too sure if the bobbin holder placement in my old machine was similar to my upgraded one. (I did not try to remove the bobbin holder then as I wasn't as brave. I actually tightened the screw with the casing still in the machine..)

But generally, the metal prong of the bobbin casing should be directly behind the plastic prong of the machine when inserted back.

But do email me with a photo, so I can have a better picture of the problem!

I have been struggling with an intermittent problem with my Zig-Zag stitch since I purchased this machine over a year ago. Many times when I would re-thread the bobbin I would get a perfect zig-zag stitch on the bottom but a messed up one on top. I read the manual and tried everything but continued to have trouble. After trying what someone posted on this BLOG about MAKING SURE YOU CATCH THE GRAY PLASTIC GUIDE BUT ALSO THE METAL UNDERNEATH it has now been working fine 100% of the time. I am so thankful for the valuable advice.

My bobbin case has that weird paint over the tension screw as well! How to I adjust the bobbin tension in that case?!

To the post above,

Hi! You would need to scrape off a bit of the paint to reveal the screws. However, do note that if your sewing machine is still under warranty, doing that might void it.

Thanks for the handy hints. Lucky I found your page or I would be still trying to figure out how to solve the problem.

I have two brother sewing machines that are giving me problems. You mention we can email you. What is your email address? Thanks.

Hi, my email is rhinestic@gmail.com. I'm not an expert at the sewing machines though.. I'll try my best to answer.. :)

Warning. I just broke my bobbin case on my Brother XL-2600i. The screws are really teeny and when I tried to tighten them they just popped off. I'm going into order a new bobbin case.

Oh no! Thank you for warning us!

Excellent advice... based on lots of terrible comments I've seen en route to this post, I think there are a lot of Brother users out there who are having this problem. If only they could read this! I just tried it and hey presto! Very happy, and a big thank you for your generosity in sharing this!

I removed enough of that paint with a sewing needle so I could turn the screw and adjust the tension

I have been having trouble with my bobbin thread being super tight.

Luckily I came across your post.

Although my bobbin case looked a little different there is a little screw so I turned it the suggested way and put it back. It's sewing like a dream now! I'm ecstatic! Thanks so much for your post.

You just saved me from stopping my project!! I’ve spent a hour moving the tension dial notch by notch and my tension was still a mess, too and bottom! I just held the guide flap down and it’s sewing beautifully!! Thank you!

Thank goodness for the search feature on the internet! Found this post and it was PERFECT to solve my tension issue. I had been lowering the thread tension and it just wasn't getting the job done. It is sewing so much better now.

Thanks!

The following time I learn a blog, I hope that it doesnt disappoint me as a lot as this one. I mean, I do know it was my choice to read, but I actually thought youd have one thing interesting to say. All I hear is a bunch of whining about something that you could possibly repair if you happen to werent too busy searching for attention. casino games

hi please helppp meee all my machine is treaded right but for some reason its not sewing anything I have no idea what it could be can any one help me out :D

Im having the same problem ^^^

Got it ! Thanks !

You are a life saver... ive been fighting this problem for an hour!!

Thank you!!! Solved the problem!

No matter how much I adjust the bobbin or top thread. It still bunches up from the bobbin side. I have a brothers project runway LS2250PRW. CAN ANYONE YELL ME WHAT THE HECK I'M DOING WRONG PLEASE .

Thank you so very much. Has been a problem for a while.

Very Informative, thanks for shearing it. small sewing machine

Post a Comment